While a lot of the more advanced 3D printing robotics projects are designed for educational purposes the Kauda robotic arm is the most widely accessible. Focus on consistency if the robot works 10 out of 10 times at your build field it might only work 5 out of 10 times at the competition When something isnt consistent analyze why and look for small changes to improve consistency.

Fllcasts Ftc Tetrix Four Omni Wheel Arm Robot

This concept can be a very effective design if done correctly.

. Introduction to Robot Wiring. Lastly the gearing on our arm to a ratio of 9 to 1 should give us an amazing amount of torque and control when lifting the arm of the robot up and over to the basket. Build and attach a servo-controlled arm to the robot.

This design is a good starting point for robot design using the REV 15mm Build System. A differential drivetrain combined with limited the amount of space between the shipping hub and the field wall makes turning in that space difficult. An arm a claw a sweeper or anything else the team can think of to help them complete the games challenges.

Robot Design and Fabrication for Ultimate Goal Intake Design and Evolution Design and Evolution The intake started as a single stage roller intakeand was developed into a 3 stage compliant wheel intake The intake was designed to use only one motor withpulleys. This section outlines the steps required to build the REV Class Bot V2. This technical video goes into d.

There is also a risk of the arm knocking into the shipping hub. Control Hub vs Robot Controller Phone Designing an arm or launcher Making your. The PushBot has 3 DC motors and 2 servos.

The wiring of a robot serves two primary purposes. PB2 PushBot 2 Purpose. The last group was working on programming the robot.

Fish in the Boat 4140 had a nice one. The other group worked on figuring out the motor that will turn the rod that will help raise the hook to hang our robot. 10132021 Introduction to this Guide About This Guide The Basic Bot Guide is designed to be a resource for teams looking for a step-by-step instructional for building.

This guide will explain each category as well as provide some suggestions for building. The TETRIX Arm and Gripper Build Guide provides a good example of how to construct a manipulator. All the parts on a robot can be broken down into the following categories.

I believe this bucket design will be one of the most useful features in competition. In a nutshell aluminum and plastic is your friend when creating the arm thick steel is not. Taking into consideration what the basic robot design was we knew we needed to make some adjustments to our path.

Assist new FTC competitors to develop a sense of how an FTC Robot is constructed with the TETRIX Robotic Construction system and is programmed in Java. Coming soon Basic Engineering Tools Safety Precautions Lessons. However modification maybe.

Its design is based around a rectangular. PROGRAMMING STEPS Getting. Tech Challenge Robot Wiring Guide Revision 1.

An arched belly for climbing over obstacles and the mountain. 2015 2016 Robot Name. One was analyzing the FTC rules while another was looking over the different types of awards.

Today we split into four groups. 53 MIT App Inventor The MIT App Inventor is an alternate platform to develop code for an FTC robot. Can focus on programming the robot behavior and not have to worry about developing the framework of the Android app.

Two joint arms are quite a bit harder to do. One of the simplest is a pulley system arm using bearings and some sort of string or cable. Each CAD and any associated text image or data is in no way sponsored by or affiliated with any company organization or real-world item product or good it may purport to portray.

Ut dont redesign the robot. Its smaller size means that it is a handy teaching tool for. The new kit has over 1400 parts and was changed based on feedback from teams to give you more of the parts that teams need for being competitive at FIRST Tech Challenge events.

Will your arm be a single joint or two joint or three. The intake was created to act like the rollers ina vacuum cleaner. This kit provides the most robot design flexibility of any kit on the market focusing on giving teams a strong foundation to build on.

6 FIRST Tech Challenge Basic Bot Guide for REV-Part 2 Game Specific Revision 1. There are a few different ways to make a robot arm move the way you want it to move. The FTC forum link is located on the bottom of any of the Quick.

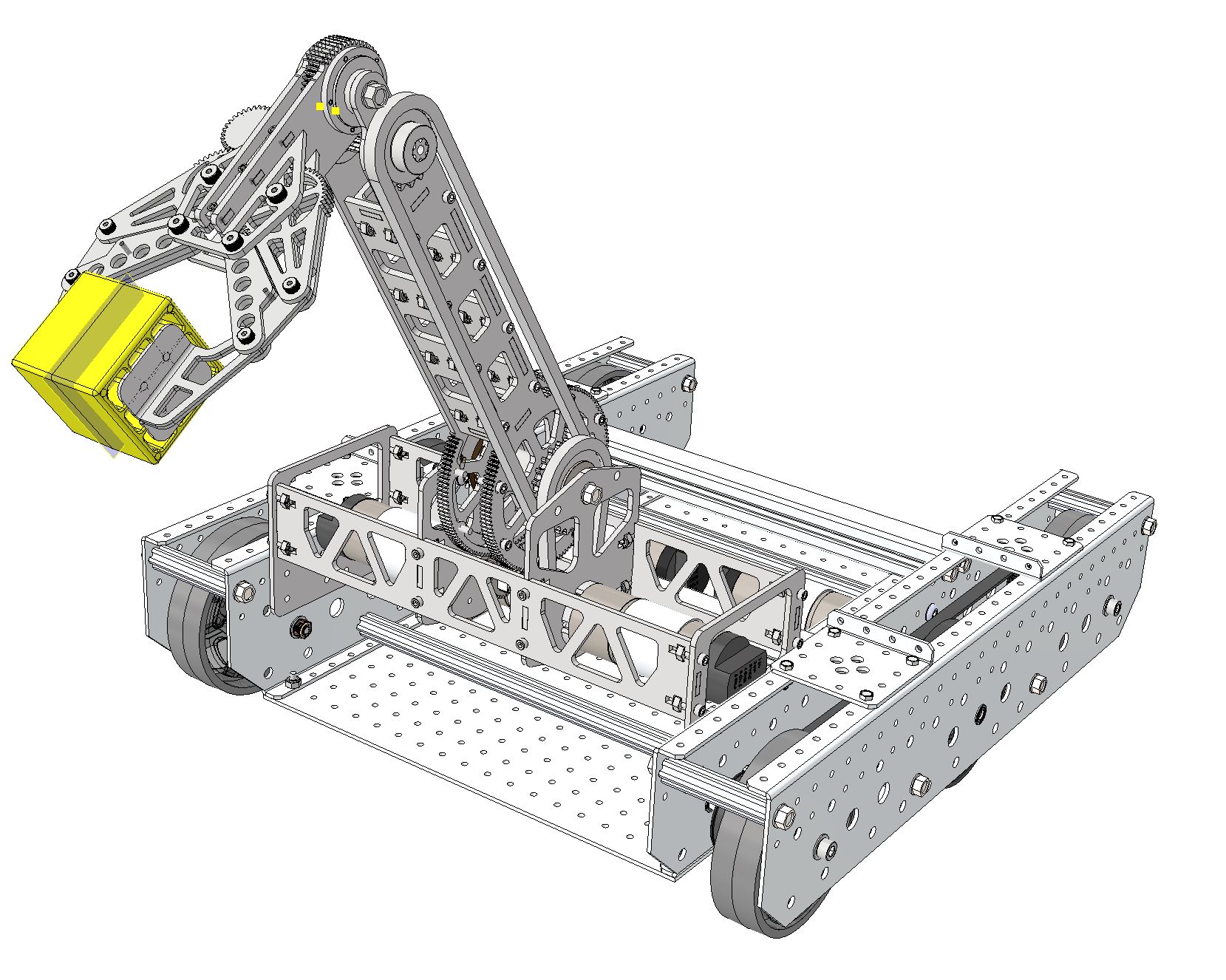

Pivot Arm VS 4-Bar Linkage Arm 4-Bar Linkage Stable in all directions of force Maintains level Carriage More difficult to make elbow for extending past length of arm Takes up more space on the robot Only approximately 130 degrees of rotation depends on distance between pivot points Pivot Arm. See more ideas about ftc robot design robot arm. A robot is built from many varying types of parts.

FTC Team 2843 United States PushBot Robot. We designed built and programmed a robot with a three degrees of freedom arm to compete in the challenge. The first purpose is to provide electrical power to the devices on a robot.

For ideas for 2 joint arms look at some of the robots from Ring it up on YouTube. Robot parts or game elements and the requirement to use only original size and unmodified fuses and circuit protection devices. A retractible fork that guides the rolling goal into position for accurate baton scoring.

Over the course of the 2019-2020 FIRST Tech Challenge season I led both the mechanical and software departments of FTC team 12788. The second purpose is to provide a communication network for the many devices that make up a robots control system. The App Inventor is a user-friendly design tool to create Android apps using a visual development environment.

Go to the FTC program and Click on the Read More link by the FIRST Relic Recovery icon. Upgraded for the 20202021 Season. The Computer-Aided Design CAD files and all associated content posted to this website are created uploaded managed and owned by third party users.

Coming soon Basics of an FTC Robot Designing a Chassis REV vs GoBilda vs AndyMark Control systems. Structure These parts are the framework to which all other robot parts are attached. 2010-11 FTC Robot Design Rubi.

Ours 4106 was pretty good too. Out of the 35 teams at our interleague competition we received the Design award. Jun 16 2021 - Explore Andrew Banass board FTC on Pinterest.

Typically manipulators are controlled using servos. A combined baton holder scorer and rolling goal capturing arm. A single joint is the best starting point.

On this page we will provide resources to help your team learn building techniques for FTC. This will involve hardware robot design and software.

First Tech Challenge Ftc Pushbot Guides Resources By Teams For Teams

Rovvver Ruckus Ftc Robot Autodesk Online Gallery

Rev Components Of A Robot Youtube

Building The Best Arm 6121 Ftc Robotics

Close Up Of Robotic Arm And Scissor Lift Ftc Bowled Over 2011 2012 Team 5485 Pro Youtube

Ftc Concept Robot Mechanisms Using Andymark Parts And Andymark Custom Waterjet Technical Discussion Chief Delphi

0 comments

Post a Comment